What Can I Do if a Spark Plug Breaks in Half in the Block

Typically spark plugs are non hard to remove as long as the plugs are replaced on a regular basis. But spark plugs tin break off, peculiarly in engines that have been sitting for long periods of time. This is why y'all hear the plight of broken plugs beingness raised by antique tractor restorers.

Understand that a spark plug is constructed like a hollow bolt. If you exceed the recommended torque during removal, the spark plug trounce can shear off below the installation hex head, says Champion Auto Parts.

If excessive forcefulness is required to remove a plug this can be traced to one or more of the post-obit causes:

- The plug was left installed for also long a time.

- Someone installed the spark plug using excessive strength.

- Someone cross-threaded the plug during installation.

- Someone installed the plug with dirty threads. To avoid this always clean the threads on plug you have removed to clean their tips and electrodes and then coat the threads with anti-seize compound. This is especially of import with spark plugs being installed in an aluminum cylinder head or in equipment that is stored outdoors.

The most mutual way to remove a spark plug which has twisted off above its hex caput is to use an extraction bit, which is oftentimes called an easy out flake.

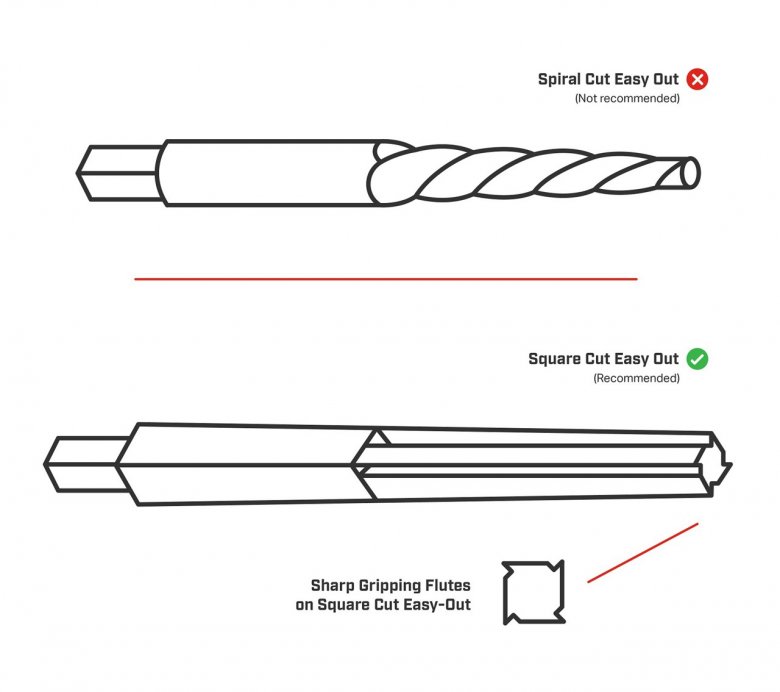

Champion Auto Parts highly recommends only using a square-cut bit every bit opposed to a screw-cut bit (encounter illustration below).

With a screw cutting flake you run a risk a greater chance of causing the broken spark plug'southward shell to expand, locking it even tighter into the cylinder head as removal pressure level is applied.

On the other hand, the square cutting type bit employs a sharp flute that digs into the cleaved plug shell to provide a strong gripping surface without expanding beat metal.

Simply before you attempt to remove the plug be sure to rotate the engine so that the piston located below the plug y'all are removing is at bottom dead middle. Too make sure the engine is cold.

Next soak the cleaved plug shell with a generous corporeality of penetrating oil. Later on soaking go savour a cup of coffee or tend to other shop chores. The key is to permit the penetrating fluid to seep into the plug's threads.

Now utilize the spiral cutting easy out bit (using the appropriate bit size that fits firmly into the empty spark plug beat).

Brace yourself while using ratchet so that the ratchets drive fits squarely on the easy out fleck. Apply firm, steady pressure level in a counterclockwise direction.

Although the required installation torque to remove a taper seat spark plugs is simply 7 to 15 feet pound, Champion Auto Parts report they have heard reports of successfully removing a broken spark plug using torques exceeding 180 foot pounds.

Hither is a reader tip on how to remove a broken off spark plug:

Maurice Pederson recently had the frustrating experience of twisting off a spark plug in his John Deere Model A. "This is not a case of restoration, since I take owned this jewel for over 40 years," the Valley City, North Dakotan relates. "Information technology was running good, just I knew it was weak on one cylinder, so I decided to practice a valve job on the tractor. Afterwards I got it running again, I thought I might as well check the spark plugs and ignition points. When I put the wrench on one of the plugs, I was actually surprised to find out I could non movement it."

Pederson continued to piece of work on loosening up the plug until. . . . yep, you guessed it, "it twisted off just below the adjacent office of the plug body."

Not wanting to take to remove the tractor's cylinder head to remove the spark plug'south base, Pederson improvised a solution yous might exist able to use.

Offset, he basis a hacksaw blade down so information technology would fit through the plug's body. And then he positioned the blade in a bayonet-type handle using it to cutting a slot through the spark plug trunk so it would collapse.

Prior to cutting, he positioned the handle so it would cutting on the pull stroke. "I cutting the slot deep on the innermost threads because I didn't desire to harm the outer threads," he says. "I ran the thread chaser in to clean up the threads" later on collapsing and removing the plug.

Before installing a new plug, he started the engine to eject whatsoever foreign matter so it wouldn't get defenseless in the exhaust valve.

Source: https://www.agriculture.com/machinery/maintenance--repair/dont-despair-a-broken-spark-plug-heres_567-ar49999

0 Response to "What Can I Do if a Spark Plug Breaks in Half in the Block"

Post a Comment